A Beginner’s Guide to Switches

Diverting a bit from the reviews of switches, I’ve been wanting to sit down more and more frequently to write documents targeting some of the things other than switches, yet still related to switches – such as modifications, lubing, frankenswitches, etc. This has been due in large part to a combination of the massive amount of support that my website has seen since it has been up as well as the slew of general questions from newer folks that I am receiving. I absolutely love getting DM’s from fans and people who appreciate my work, and more and more often I’m receiving messages from people who haven’t even bought keyboards yet, let alone really started looking into the newer, higher end switch market. Thus, as a result of this I’ve tried to outline and detail this document as thoroughly as I can simply so that anybody of any skill level should be able to read it and follow along.

As well, as a little bit of a personal side note, within the last week I’ve received a large package of switches from a fellow collector that has helped push my collection to a size that even I had never anticipated it getting to – 700 unique switches. Honestly, its completely mind blowing to me that I not only have that many, but that I still have several packages in the air that are going to keep upping that count. So, in addition to thanking the people who have supported my reviews and my website, as mentioned above, I wanted to carve out a little space to thank anyone and everyone who has helped contribute to my collection – I wouldn’t have been able to nab most of my most cool, interesting, and unique switches without all of you.

Mechanical Switches - From The Top

This is going to be the absolute starting point if you are just getting into mechanical keyboards and have not the slightest clue what is going on. If you are reading it and this does describe you, then I’d like to welcome you first and foremost to the hobby. There are a lot of nuances and intricacies to all of this and to building mechanical keyboards, but by and large you can get away without having to know every single detail about every single piece and part you use. That being said, one thing that you can’t build a mechanical keyboard without is switches – and it does benefit you to have a solid working knowledge of the different components within switches. If you’re wondering why I put these above other components in terms of importance to understand, its because these make up the heart of your keyboard, and are what allow it to be specifically tuned to how you want it to feel when you type on it.

Figure 1: They may sure look like pretty colored Tide Pods, but I would not recommend eating them.

Switches are the physically ‘mechanical’ part of a mechanical keyboard and sit underneath each keycap on a keyboard. Rather than relying on tiny electronic circuits sandwiched within a rubber membrane underneath each key like most modern Dell and HP keyboards have, these ‘switches’ have an entirely different construction and mechanism that allows them to operate. Referring to the gif of a switch being used, below, you’ll notice that there are several different colored moving parts that don’t quite have a name yet – but they will here soon. Simply looking at how a switch moves in this gif, though, you’ll begin to see that rather than a short little press like you’d have on a laptop keyboard, which has the aforementioned rubber membrane in it, you’ll see that there is a relatively long stroke from where the red part starts up in the air and finishes in line with the black piece behind it, which represents a single key press.

Figure 2: Keyboard switch internals in action.

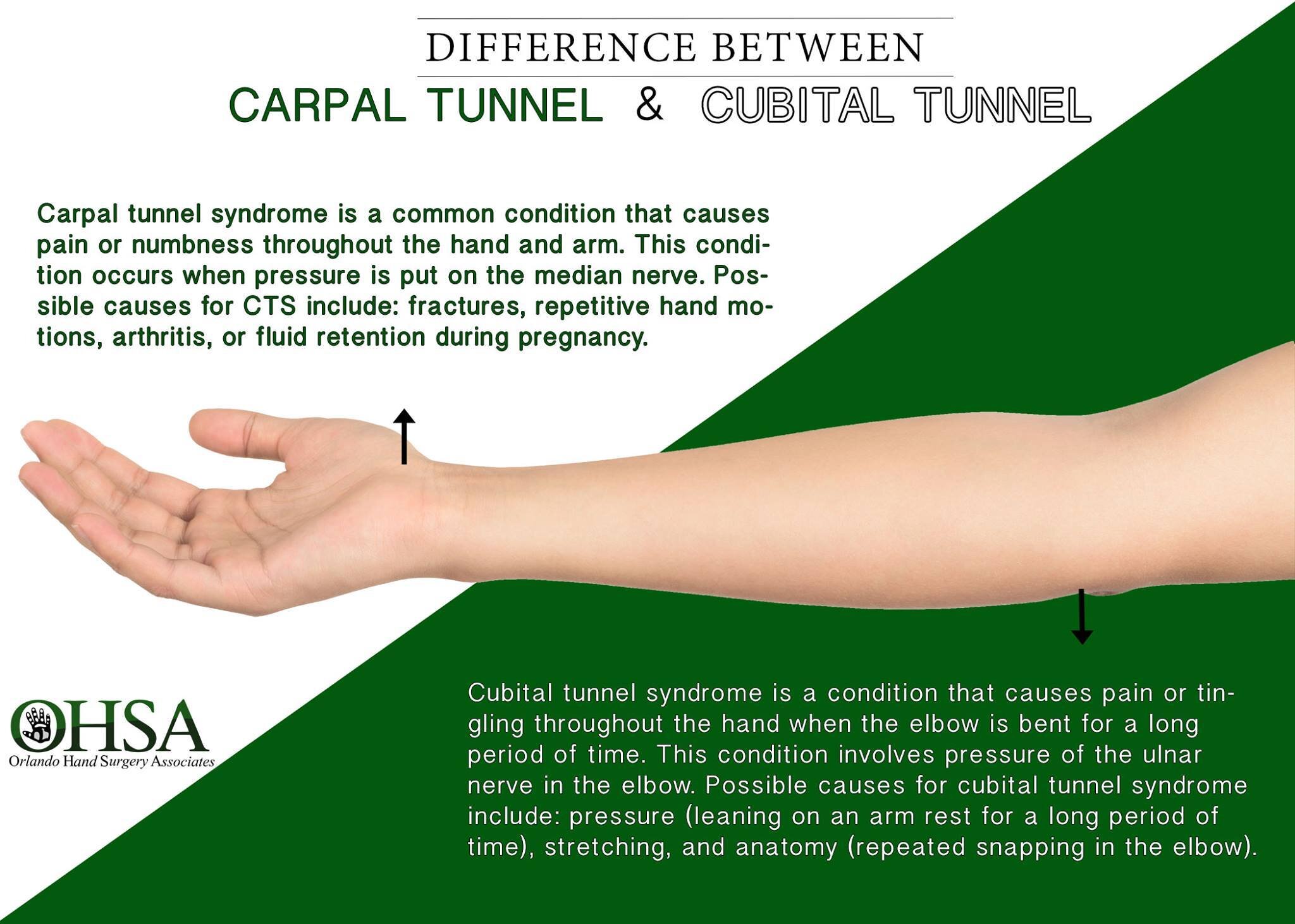

Looking at how this switch moves and how it travels so much further than a rubber membrane switch like in a laptop or modern keyboard, you might honestly be thinking to yourself right now: “What the fuck, Goat? These are just stupidly complex for no reason, aren’t they?” And while you are correct that they are more complicated mechanically than a rubber membrane keyboard, there are strong benefits to using these versus rubber membranes regardless of how you use your keyboard. Namely, the largest benefit to mechanical switches over rubber membranes is a reduction in repetitive strain injuries (RSI) over long periods of usage, with sub-benefits in comfort, longevity, and customizability. If you type a lot for school, game all throughout the night, or are simply using a computer for more than a handful of hours a day, you can effectively put yourself at risk of RSIs such as carpal or cubital tunnel issues using normal keyboards.

While this may verge on preachy a little bit, RSIs are a serious concern that a lot of people are beginning to experience earlier and earlier on in life as we push toward a more computational-centric workforce and learning style. (I mean, we did all just get out of a quarantine forcing us to work from home and take online classes as an entire world.) I, myself, am no stranger to this as even though I have no family history of arthritis, or carpal tunnel issues, I was diagnosed with acute inflammation of my cubital tunnel when I was 19 years old – requiring surgery similar to a carpal tunnel release because I was at a point where I was put to tears trying to grip a pencil. The doctor had said that I was the youngest case he had ever seen of cubital tunnel issues by 20 years. Shortly after this surgery, due to my returning to sophomore year in college, I picked up my first mechanical keyboard in order to help with typing papers for college – and I can unequivocally say it was one of the best purchases of my life.

Figure 3: I get that it is a bit of a large infographic, but I think it is an important read for everyone.

Veering back from the personal segue a bit, it’s hard to explain without getting too technical how mechanical keyboards can benefit and prevent RSI injuries over the alternative rubber dome keyboard, so I will instead offer an analogy. Consider you are repeatedly poking your finger quite hard into a sponge versus a pretty solid rubber mat, like a gymnastics mat. After a long time of pressing it in, regardless, you are going to start feeling a bit of pain in your fingers and probably up through your hands and arms from jamming your finger into these materials. However, as a result of there being more give and distance that your finger can travel into the sponge versus the rubber mat, your finger isn’t going to hurt quite as much or nearly as quickly. As you may have noticed before, sure, mechanical switches do have a lot more travel and complexity to their motion than your laptop membrane or your phone keyboard, but that extra distance and the design of the internals is what allows you better cushion your fingers and protect from RSI injuries and the damage of typing over extended periods of time. While you should always take breaks and properly stretch your hands and fingers prior to long periods of typing as damage can still occur even with a mechanical keyboard, it allows you to operate for longer periods of time without stress.

In addition to the travel cushion preventing RSI injuries, there are people who have weaker fingers, hand issues like arthritis, or any number of conditions that make typing on normal keyboards difficult or painful. The beauty in mechanical switches, and one of the sub-benefits mentioned above, is that they are highly customizable with respect to the force required to press them, their feeling, and even their travel distance – all of which can be tuned to not only your preferences, but to actually better ergonomically suit you and your needs as someone who uses a keyboard. As well, the board shapes, angles, and designs themselves can even be modified in order to support those with specific ergonomic needs or desires, though since my interests are primarily in switches, I won’t go into the details surrounding these design choices. In this next section, we are going to dive into the anatomy of a switch and breakdown a description of all of the different parts and pieces within so that you have a better understanding of the internals and can fully immerse yourself into the terminology that is used by people regularly within the mechanical keyboard scene.

Switch Anatomy 101

In this section, I’m going to break down the five main components of a mechanical keyboard switch and discuss some of the variations and differences in some of these parts that you are likely to see if you spend some time in this hobby. I want to make clear, though, that this is by no means a comprehensive breakdown of all the different variations in switches that exist, as vintage stuff in particular is rife with wacky experimentation and different ideas that fell out of practice almost immediately after their initial design. By and large, if you read this section you should have a working knowledge of most modern mechanical keyboard switches that you are going to come across. Thus, to start, please refer to Figure 4, which is a blow-out diagram of switch components. We will walk through these parts in numerical order and discuss the subtle variations in each that matter.

Figure 4: Switch component diagram.

Part 1: Top Housing

Referring to the blow-out diagram, you’ll see that the Top Housing (#1) is the same color as the Bottom Housing (#5) and combined these two pieces form the complete ‘Housing’ which holds all of internal mechanisms of a switch. In this section, we will talk specifically about the top housings, some of their specific parts, and some of the differences that you will encounter with them.

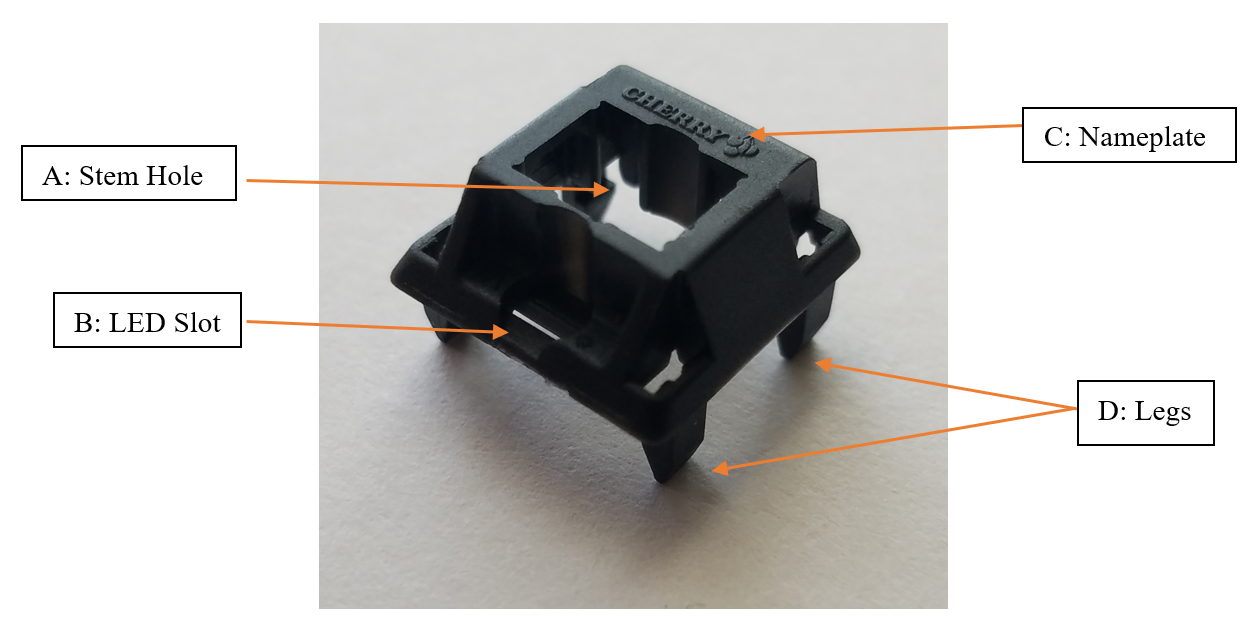

Figure 5: Cherry switch top housing with labeled parts.

Looking at the labeled example diagram of a switch top housing in Figure 5, you’ll see that there are 4 distinct regions within these pieces. The first of these parts is the Stem Hole (A). This giant hole in the center of the top housing is where the Stem (#2) is located during normal operation. As you can see in the gif in Figure 2, this is the hole where the stem slides up and down as a switch is pressed. There are no real variations to this specific part worth noting as most modern switches feature the same large, rectangular hole in the top housing for the stem.

The second labeled part of the Top Housing is LED slot region (B). This slot – which has several different variations depending on the switch type and mechanical keyboard that you are using – is where the pins of an LED are held if your keyboard support per-key LEDs. When the pins are put through this slot, they will go down into the circuit board (PCB) below the switch, and the LED will be left sitting adjacent to the top housing, as can be seen below in Figure 6. Note, this is not necessary to have in all switches when building a keyboard if you are not choosing to manually install LEDs or if your keyboard PCB does not support such.

Figure 6: An example of how LEDs sit in Cherry housings in a completed keyboard.

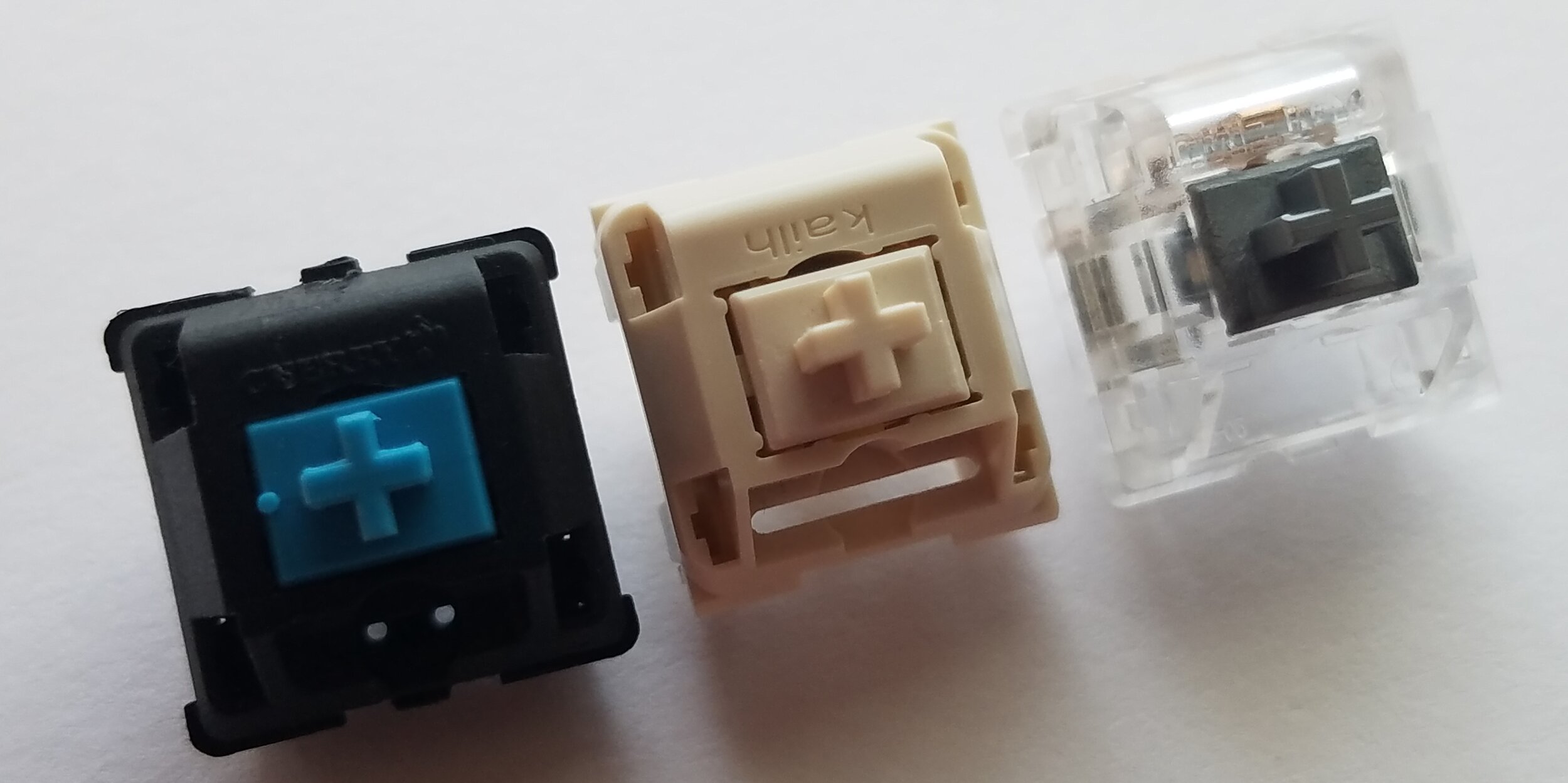

Some of the variations of the LED slot regions (B) can be seen below in the following picture. The leftmost top housing, which is a Cherry branded switch has an LED slot that is circular and allows for the top housing to slightly support an LED when the pins of it are thread through the top housing gap and the LED is left to sit in its normal usage slot. More commonly, though you will see an LED slot like the switch in the center – which has a long rectangle through which the LED pins can be thread through. Additionally, worth noting is that there is a minor variation in this center, rectangular style in which a thin plastic bar spits this rectangle into a Left and Right half, though this is purely cosmetic. And finally, another uncommon variation but important one to note is a type of top housing seen on the far right with no LED slot. There are a line of Outemu branded top housings that have no LED slot cutout and instead have a solid sheet of plastic over this spot – thus preventing usage of LEDs in this LED slot. (While it’s difficult to see in the photo, I assure you that it’s a solid plastic piece across, which was chosen in order to slightly modify and tighten the tolerances on the top housings in this switch.)

Figure 7: Picture of different LED slots featuring a (L-R) Cherry MX Blue, Novelkeys Cream, and Outemu No-Slot Top Silent Linear.

The only other thing worth nothing about LED slot regions (B) is that there are two different ‘designations’ when seeing these in a keyboard. Some keyboard PCBs support ‘North Facing’ or ‘South Facing’ LEDs. This simply means that the orientation of the switches from a top-down view is changed such that the LED slot is facing up (North) or down (South). There are not cosmetic differences in the switches specifically needed to designate North/South facing LED slots – it is completed build specific.

The third part of the top housing, and one of my favorite parts of a switch is the Nameplate (C). The Nameplate, as you’ve seen above with the picture detailing the different LED slots is where switch makers brand their switches with their company name. There are a lot of different companies that have made mechanical keyboard switches, though the names that you might be most familiar with if you look at a lot of switches are Cherry, Gateron, Kailh, and Outemu. That being said, these are not the only names that appear in nameplates – and there are a metric ton of Chinese knockoff brands with random names to the top housings. As well, some companies may not even choose to brand these nameplates at all, and instead opt to leave them blank. Nameplates (C) serve no other purpose than cosmetic design choices.

The fourth and final part of the top housing to be discussed are the Legs (D). These slim black pieces that you may have noticed peeking out of the bottom of the Top Housing in the initial blow-out diagram of a switch. These are simply used to attach the Top Housing to the Bottom Housings (#5). While you would think that that is all there is to say about these, it is worth mentioning here that there are two different variations of these, as can be seen below in Figure 8.

Figure 8: Winglatch style top housing (Left) compared to a 4-Pin style top housing (Right).

While the two variations in Legs (D) functionally serve the same purpose of attaching the Top and Bottom housings together, they simply do it in a different fashion. On the left you will see a ‘loop’ that forms what is known as a ‘Winglatch’ style connector and while it is kind of uncommon in the modern mechanical switch scene, it is still seen from time to time. The much more common top connector type is the ‘4-Pin’ type, as can be seen on the right. These are given the name ‘4-Pin’ tops as they have 4 attachment legs (2 Left and 2 Right) that latch onto the bottom housing. As well, this style of top housing connection scheme is often divided along brand lines, with Kailh and Hako branded switches being more likely to have the Winglatch style connector, and brands like Cherry, Gateron, and Outemu having the 4-Pin tops.

Part 2: Stems

The Stem of a switch, which in the blow-out diagram is represented as the brown colored piece, is what gives a switch its ‘character’ and is often the most discussed and considered portion of any switch when it is released onto the market. The shape and design of a stem is what dictates whether the switch fits into one of the three main categories of switches – Linear, Tactile, or Clicky. After discussing the general anatomy of a stem in the same fashion as the Top Housings (#1), I will then discuss the differences in stem designs which give one of these three characters.

Figure 9: MX Style stem with parts labeled (and propped up by my lovely switch opener).

Looking at the diagram of a general stem, above, you’ll see that there are several regions of note that need to be considered when discussing stems. The first feature to discuss is the ‘Keycap Mount’ or ‘Mount’ (A). This portion of any stem is what protrudes out of the Center Hole of a Top Housing (#1) and what actually attaches a keycap to a switch. While there are innumerable different types of mounts when it comes to vintage style mechanical keyboard and switches, there are a few different types worth discussing that you may come across.

In the following picture, Figure 10, there are several different traditionally recognized keycap cross-mounts. The one in the top left corner represents the traditionally recognized cross-mount. This is by far the most commonly seen of mount designs and supports the vast majority of modern keycap sets. The next two designs for mounts to the right of the first one are also fairly common and still fit the same keycaps that a normal cross-mount style would. The partially enclosed cross mount (left) is what is known as a ‘Dustproof’ mount, which was named after their initial design intent of keeping switch internals cleaner over long-term usage. The third, entirely closed mount are what are known as ‘Box’ mounts. Note, the reason that these are named Box mounts is not because there is ‘a box around the cross’ but rather because this style of stem mounts are generally seen on Box style switches, which get their name from a box-shaped internal mechanism. The fourth of the mounts, which features two holes like an American electrical socket are only seen on Low Profile switches, and thus these are called ‘Low Pro’ mounts. The final mount on the bottom right, which features a singular horizontal rectangle is what is known as an ‘Alps’ Mount. These were given the name based on the original manufacturer of these style of switches, Alps Electric. While these are vintage switches and very rarely will you encounter modern equivalents of these mount styles, they are among the most recognizable and usable vintage switches, which is why I chose to include them.

Figure 10: Different common switch mounts. (L-R, Top-Bot: Greetech Razer Yellow, Outemu Dustproof Blue, Novelia, Kailh Choc Low Profile Red, Alps SKCM Amber)

The second feature to discuss is the Center Pole (B). While serving relatively little functionality as compared to the rest of the stem, this helps as a guiding tool to help keep the stem centered as it moves up and down during activation in a switch. As we will see in a bit, this center pole (B) will travel into a specially designed hole in the center of the Bottom Housing (5) that helps keep the stem from wobbling side to side within the switch when all the way pressed down. Past this basic functionality, there is not much variation in common design past this point.

The third feature to discuss arguably serves even less of a purpose than the center pole (B) when it comes to the design of the stem – the Front and Back Plates (C). The front and back plates of a stem refer to the flat, rectangular regions connecting the left and right side of a stem together. While these are not commonly called in this fashion (yet), I refer to the front plate as the rectangular piece sitting between the legs (E) of a stem and the back plate being the opposite side. These simply serve as structural points to help strengthen the stem design, with the front plate being the point from which the legs (E) extend outwards. As well, it may be worth noting that since most stems are made from plastic injection molding, some switch manufacturers have traditionally used the backplate as an injection point for molds and you can occasionally see sprue marks in this location.

The fourth feature of a stem to discuss – and one that plays a massive focus in the modification side of switches – are the Rails (D) on either side of the stem. These, much like the center pole (B) help guide the switch along a completely vertical path as they fall within and slide along the matching rails in the Bottom Housing (#5). Unlike the center poles (B), however, these rails are the main guiding points of the stem and make the majority of the contact between the stem and switch internals. There are two main variations to the Rails (D) of a stem, as can be seen in Figure 11 below. The stem pictured on the left features a normal rail while the stem on the right features an additional piece of rubber which sticks out towards the top and bottom of the rail. These rubber pads are commonly seen in what are known as ‘Silent’ switches and are used to dampen the sound of a stem when it makes contact with the Bottom or Top housings of a switch. While the particular rubber silencing pads on this switch stem are colored black, many are often colored clear or a very light white color, which may make them hard to identify in a closed switch.

Figure 11: Picture of an Alpaca stem (Left) compared to a Silent Alpaca stem (Right).

The fifth, final, and definitely most intricate stem feature is what are called the Legs (E) of a stem. The legs of the stem are the two little slanted outcroppings from the Front Plate (C) of a stem that interact with another switch component known as the Leaf (#3) ,which will be discussed in a bit, in order to actuate the switch as well as produce the linear, tactile, or clicky characteristic of a switch. As can be seen in the switch operation gif in Figure 2, as a switch is pushed in these legs that stick out will push against the Leaf (#3) and release pressure at different points in the stroke, causing it to move in and out to complete and break the circuit which registers a keystroke through that switch. The movement back and forth of the Legs (E) across the Leaf is where both the character of a switch comes into reality as well as where the design of the legs of a switch become important.

Figure 12: Picture comparing the stems of an Alpaca (Pink; Linear) and KBDFans T1 Night (Teal; Tactile).

Since it is much easier to describe the general mechanisms behind linear and tactile stems, above you will find a side view comparison the design of a linear stem leg (left) and a tactile stem leg (right) in Figure 12. With the linear stem on the left, which comes from an Alpaca switch, you’ll notice that the legs are straight and completely smooth from top to bottom, whereas the tactile stem on the right, which comes from a KBDFans T1 switch, has a significantly more bumpy path. As I’m sure you can piece together, the bumps along the legs of this stem are what produce the ‘tactile’ bump feeling as it travels along the Leaf of the switch whereas the ‘linear’ is smooth and consistent. While there isn’t much variation in linear stems, tactile stems have a wide range of variation as the actual shape of the bumps can drastically affect how strong a tactile bump is or how large it feels (is it throughout the entire push or only a short blip).

Figure 13: Picture comparing the shapes of different tactile switch bumps. (L-R: Cherry MX Clear, Zealio V1, Arctos 62g, and MOD-M)

Completely deviating from linear and tactile stem legs, though, clicky switch legs get much more complicated based upon the mechanism that is being used to produce a click. While clicky switches, in general, are a bit less common than the other two types of switches, they do still share a relatively popular portion of the market with respect to entry-level mechanical keyboards. Looking at one of the most common beginner clicky switches – the Cherry MX Blue – we will explore the concept of a click-jacket mechanism for producing a click in a switch.

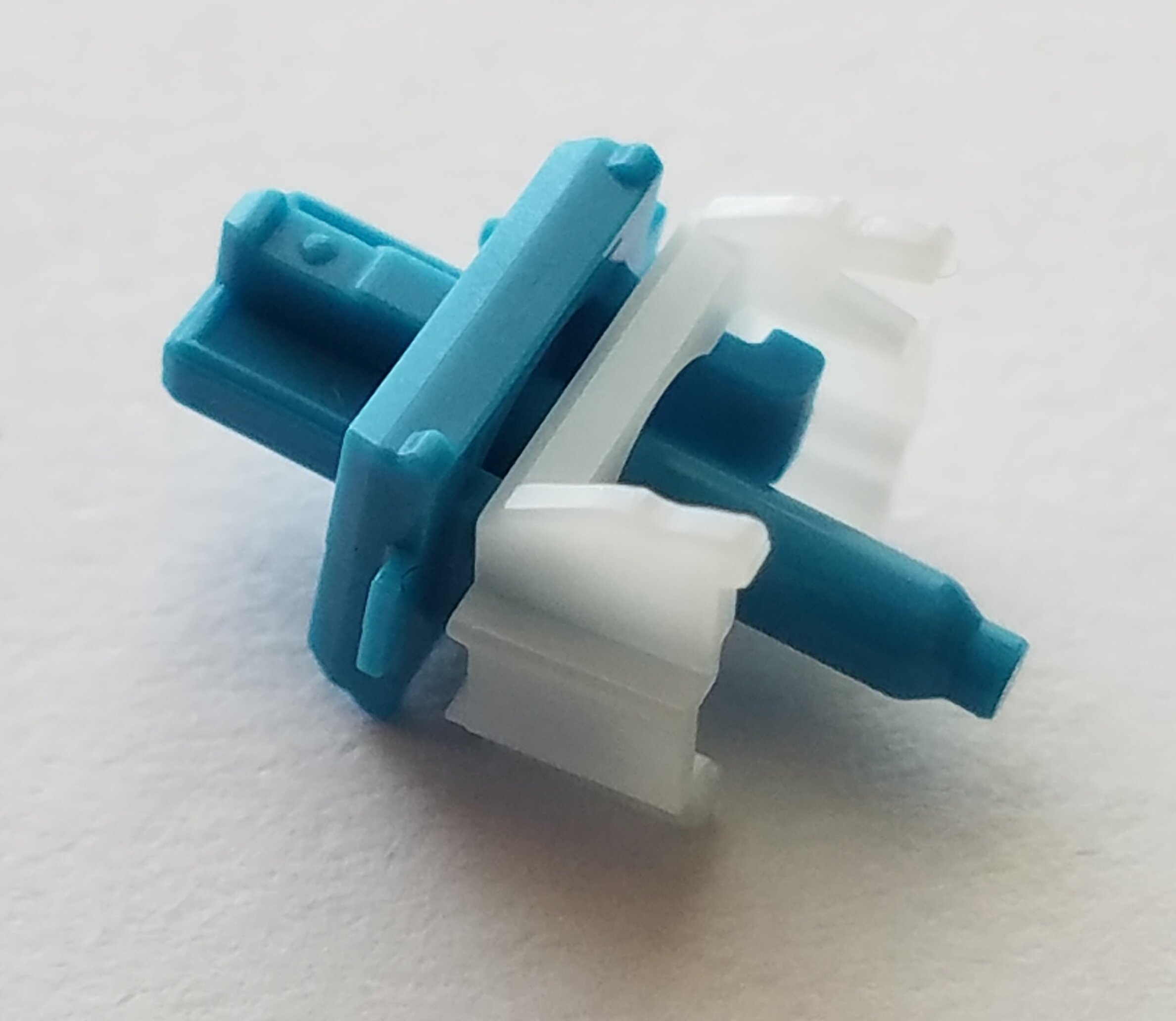

Figure 14: Picture of a Cherry MX Blue stem which features a ‘click jacket’ style mechanism for producing a click.

Looking at the picture of an MX Blue stem, above in Figure 14, you’ll notice that there are some stark differences as opposed to the anatomy that we have just walked through for stems. In click-jacket style stems, there are essentially two pieces – as seen here in blue and white. The blue portion of the stem contains the Mount (A) and the Center Pole (B) and the white portion of the stem, which is referred to as the ‘click jacket’ contains the Legs (E) of the stem. As well, you’ll notice a complete absence of front and back plates (C) on either of these pieces. Rather than have these two components fixed together, as a click-jacket style switch is pressed, the interaction between the legs of the click jacket and the Leaf (#3) causes the jacket to ‘bounce’ up and down, producing a clicking noise as it rattles up and down the stem.

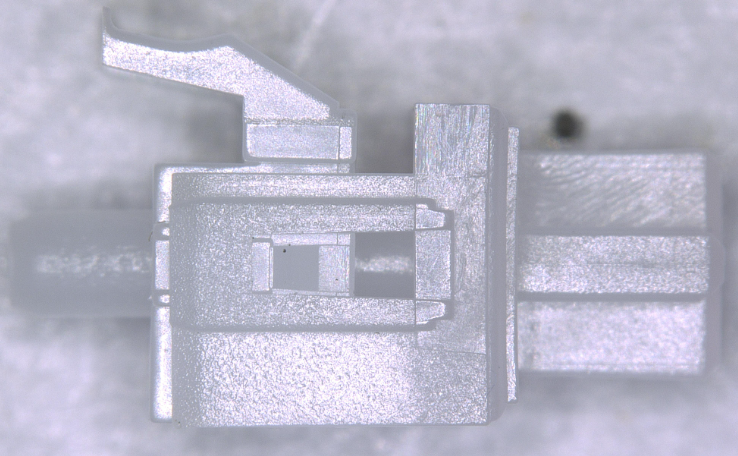

The second of the click style stems come in the form of what are known as ‘Aristotle style’ stems and are a bit of a hybrid between a one-piece stem and a click-jacket style stem. Deriving the name from the vintage Aristotle boards that these clicky stems were derived from, pictured below is a slightly modified and modernized version known as a ‘Phoenix’ stem, from Outemu. Rather than having a completely separated click jacket, you’ll notice that the loose portion of the stem is relegated more towards the legs whereas the rest of the stem stays in roughly the same form as tactile or linear style stems. Additionally, though not pictured here, these stems still have a back plate.

Figure 15: Amazing close up photo of a Phoenix stem with an “Aristotle Style” click mechanism. (Credit to u/basecase01)

The third and final common click style stem comes in the form of a further gradual step along this progression into a singular, one-piece clicky stem. Rather than having a click mechanism that is produced by the Legs (E) of a stem, the final version of clicky style stems have an extrusion, similar to a Leg, from the Back Plate (C) of the stem, which rakes across a ‘click bar’ which is attached to the Bottom Housing (#5) of the stem. For click bar style switches, which can be simulated by flicking your finger across one of those old spring-style door stops, the stems and bottom housings are specially designed to work with each other and don’t work well with other styles of stems. These has long been considered by many people within the custom scene to be the ‘best’ style of click stem as it often produces the loudest and sharpest sound of any of the click style stems.

Figure 16: Picture of a Novelkeys Sherbet Stem and bottom housing demonstrating a “Click Bar” style mechanism for producing clicks.

Part 3: Leaves

The leaves of a mechanical switch, which were represented by #3 on the original blown-out diagram (Figure 2) are the least discussed and most complicated aspect of a switch. Coming in two separate pieces, these metal contacts always come pre-assembled within a switch and pretty much are never modified or swapped between switches. As seen below in a picture detailing the two different metal pieces which make up a switch’s leaf, the long slender pins towards the bottom are inserted through the bottom housing of a switch and stick out the other side. These two pins are what are physically soldered into the PCB underlying the keyboard and are what establish the electrical circuit that registers a switch stroke when the switch is pressed in and the two separate components make contact.

Figure 17: The two metal pieces that combined make up a switch’s leaf mechanism.

Looking at the above picture, the larger leaf portion on the left is what faces the inside of the stem and the two protruding arms that are physically lifted off the table are what interact with the stems of the switch. Inside of a switch, the smaller piece is flipped over along its west axis and is placed slightly in front of the other metal leaf. In a normal, un-pressed state, the legs of the Stem (#2) actively separate these two metal leaves, and as the switch is pressed, the legs of the stem travel along the leaf, allowing it to come closer to the smaller metal leaf in front until it makes contact. Once the two metal leaves are connected, a circuit is completed, and a singular keystroke is registered through the circuit board underneath the switch. The original gif diagram which details this is again shown below in Figure 18.

Figure 18: Sure, it’s the same gif as above, but I hate scrolling back and forth too.

Due to the rather fragile nature of these leaves, they are often never removed from the Bottom Housings (#4) after they are installed by the factory. That being said, some factories design slightly different leaves to better interact with tactile versus linear stems depending on the switch to be constructed. Often simply referred to as ‘tactile leaves’ or ‘linear leaves’, these types of leaves tend to work best with their respective style stem. To be entirely honest with you, I don’t know much more about the differences separating tactile and linear leaves apart from each other and I couldn’t really find any documentation that well explained it to me, either.

Part 4: Spring

Second only to the Stem (#2) in terms of importance to a switch’s ‘character’, the spring of a switch is what provides the weight of a switch. Unlike the other parts in a switch, there aren’t little nuanced details about the appearance of springs, rather their interesting features are tied up in their performance and in the ‘type’ of spring bought. While there are several variations in spring appearance, with minor differences in ‘thread per inch’ count and number of connected coils towards the top and bottom of a spring, the only main cosmetic difference discussed is the ‘material’ which springs are made out of. While springs are almost always made out of steel, these can come in black, silver, or can even be gold-plated, as can be seen below in the following picture. While gold springs may certainly look more pretty, there is no evidence that I am aware of that suggests they perform better than their silver counterparts.

Figure 19: Picture of different spring finishes from an Aliaz switch (Black), Silent Alpaca (Gold), and Novelkeys Cream (Silver).

With respect to different spring ‘types’, there are several different designations that can be given to a spring to describe how the force it provides to a switch changes over the course of pressing a switch. The three main ‘types’ that springs are lumped into include Linear, Progressive, and a relatively new and slightly less common type called Complex. Linear springs, as their name implies, provide a linearly increasing force throughout the entirety of a switch being activated. Following the names again, progressive springs are referred to as such as they progressively increase their force as the switch is pressed further down. Whereas a linear spring may provide a force that linearly increases to 68g throughout the stroke, a progressive spring could start off at the same arbitrary starting force and increase to 120g of resistance in the same distance as the linear spring. Complex springs stand as a bit of a hybrid between these two spring types, starting out linear in fashion but transitioning to a progressive style part way through the stroke of a switch.

Now aside the ‘type’ of spring, there is another metric discussed with springs that I worked into the previous descriptions – weight. Spring weights vary drastically across the spectrum of pre-built available switches and even more so in the aftermarket scene. Typically, a reasonable range to except for pre-built switch spring weights are between 45g and 78g of weight. Worth noting, as well, that you may encounter the force of grams reported as cN (centinewtons) instead, though you can assume the numbers to be roughly the same as 1 gram is about 0.98 cN in force. As well, you will see these weights discussed by people and vendor in terms of ‘actuation force’ or ‘bottom out force’. While these terms may seem confusing, it makes sense when you consider that switches don’t have to be pressed fully in in order to complete the circuit in the Leaf (#3) and thus there is a point between the start and end of the press in which a switch is ‘activated’. These terms simply refer to the weights of springs with respect to this point of activation versus the weight of resistance when a switch is pressed fully inwards.

Figure 20: This is literally just the MX style springs offered from a single aftermarket vendor - there are lots of variations. (Intentionally low resolution to make it fit)

Now that you understand how springs work within a switch and how they are marketed – there are two more common pitfalls that need to be discussed in order for you to truly have a solid grasp on these. First, the concept of an ‘activation’ force really is a bit of misleading marketing with respect to aftermarket stems. The reason I say this is that as we have seen above, Stems (#2) are different for tactile versus linear switches, and thus interact differently with a leaf. In fact, this interaction with the leaf regardless of the stem type causes a slight bit of upwards force at the point of activation in a switch and can effectively ‘change’ the spring weight. Thus, if you use the same spring with two different types of stems, it may have a different ‘actuation force’ as a result of the interaction between it, the stem (#2) and the leaf (#3). In order to avoid the common pitfall of this poor marketing that occurs, its always best to consider the ‘bottom out’ weight of a spring over the ‘actuation’ weight or force. The second caveat to springs is much easier to grasp in that much like we saw with the different stem (#2) mounts, there are special types of springs for Box, Low-Profile, and Alps switches and these can not be interchanged with normal cross mount (also called MX style) or dustproof style mount switches.

Part 5: Bottom Housing

Last but most certainly not least, the final piece to a switch is the Bottom Housing. Bottom housings, as discussed in the Top Housing (#1) section, combine to not only form the complete housing, but also hold the switch internal components, and mate the switch to the printed circuit board in a keyboard. While these are awfully complicated looking in nature, I’m going to break down the regions of this switch into two different sections – one looking at the inside of the bottom housing and one looking at the outside of the bottom housing, as these both have very special things to consider.

Figure 21: Inside of a Novelkeys Cream switch bottom housing with parts labeled.

Looking first at an internal view of the bottom housings, the different points of interest are much more distinct than in the previous piece diagrams. As you may have already recognized, the region labeled ‘A’ is the Leaf (#3) and as discussed in that section, it has already come pre-inserted into this switch housing bottom. Continuing to build off of previous sections, the ‘Center Mast’, labeled as B in this diagram, is where the Stem (#4) center pole sits in a closed switch to help guide the switch perfectly straight up and down. As well, you’ll notice that region C refers to the ‘Slider Rails’ and are the counterpart to the rails on either side of the stem. Much like the center mast, these help to guide the switch in a completely vertical path. Finally, the last region labeled on this diagram, D, refers to the tiny holes sitting opposite of the leaf in the bottom housing. These tiny holes are for pins of LEDs that help guide them into their desired slot on the PCB underlying the switch when they are thread through the Top Housing (#1) as seen in that section.

Figure 22: Bottom of a Novelkeys Cream switch bottom housing.

Moving to a bottom view of the bottom housing of a switch, you’ll notice that I’ve included two different variations but only labeled one part. I chose not to label the Center Mast (A), the Leaf (#3) pins, and the LED Slot (D) as I can assume that you inferred that these are what they looked like on the outside. (Note: If the Center Mast is not completely sealed on the bottom side of your switch bottom housing, it is okay – this is just a cosmetic choice from the company.) The regions that I’ve chosen to highlight are these two little plastic legs that sit on the right- and left-hand sides of the switch in Figure 21 above. These are what are known as ‘PCB Mount Legs’ and are insanely important to note when buying switches for a mechanical keyboard. In fact, switches will be marketed as ‘PCB mount’ if they do have these plastic legs and as ‘Plate mount’ if they don’t have these legs. An example of these two variations may be found below in Figure 23.

Figure 23: The two main switch variations in bottom housings: Plate Mount (Left; Grey) and PCB Mount (Right; Olive)

Now the reason that these PCB Mount Legs matter so much is they are what effectively allow you to secure you switch to the circuit board underneath. Depending on what type of PCB you are building with, you’ll note that there may or may not be an extra set of holes on either side of the big hole where the center mast of a switch bottom will go. These little holes are there in a PCB specifically to accommodate these little plastic legs on a PCB mount switch. They are there to provide support such that you could put this switch directly onto the circuit board and a keycap on top of that and use it without it wobbling. If your PCB does not have these tiny holes we’ve discussed, then it is suited for plate mount switches and thus in order to support the switch from wobbling, your keyboard requires a middle plate to hold your switches steadfast in their current position, as you can see in Figure 24, below. Due to this difference in how the switches are actually mounted onto the keyboard, you must always check to see if your PCB supports PCB mounted or Plate mounted switches. As an extra little rule of thumb, PCB mounted switches (the ones that have the little legs) can be converted into plate mounted switches in the event that you accidentally have bought these instead of plate mounted switches. Since the PCB mount legs are simply little pieces of plastic, you can use a cutting tool to snip them off to convert your switches permanently into PCB mount legs. When doing this make absolutely certain not to accidentally clip the center mast or the Leaf (#3) pins that sit close to these legs as well.

Figure 24: Side-view diagram demonstrating how a PCB mount switch (Left) and Plate mount switch (Right) appear in a constructed board.

Much like the Spring (#4) section, there are two more caveats to the outside of the bottom housings that you should be aware of in case you encounter them. First, if you encounter a metal leaf pin that is bent, then you can bend it back into its vertical position, but you absolutely must do this with care as these pins are quite fragile. The second caveat is that there is a variation in bottom housings that are becoming more and more popular with some gaming companies that you may encounter. If you happen to get a switch with a completely flat bottom, as seen below in the following picture, don’t be concerned – these are just a different style of switches called ‘Optical’ switches. These don’t work with the PCBs that make up the large majority of the mechanical keyboard scene, so I would avoid them if you happen to chance across them in the aftermarket.

Final Thoughts

So, there we have it! If you’ve made it to this point in the document without skipping through sections and feel like you’ve at least learned something than that is absolutely fantastic. If you are still confused about some stuff and/or you feel like you don’t know everything that is going on, then you are still perfectly fine. So often newer people into this hobby feel like they need to be able to build a keyboard right away and if they struggle even understanding or buying a single component then they want to throw their hands up in frustration. Everything that I have learned, both in this document and outside of it, has come as a result of a long time of talking to people, asking questions, and simply consuming as much media as I can about keyboards, switches, and just the scene in general. If you are truly interested in this hobby and want to look further into a lot of the nitty-gritty details underlying the scene, my recommendation would be to check out a lot of different sources (including my own in shameless self-plug fashion) and to never stop trying to learn. For that reason, I will sign off this document by pointing to the list of worthwhile reads and watches in my further reading list, below, to learn more about keyboards. Welcome to the hobby!

Further Reading

A vast repository of mechanical keyboard knowledge in wiki format.

A great forum that I use to keep up on Interest Checks and Groupbuys.

Another great forum for keeping up with similar stuff to Geekhack.

A more vintage-centric mechanical keyboard forum.

A great up-and-coming site for switch details and tid-bits of information.

A great repository of keyboard streams done on nearly everything.

A great repository of similar keyboard streams to TopClack.

TheBoardPodcast YouTube Channel

A great keyboard podcast to listen to instead of watch.

High quality build videos in great production value.

Another high-quality all-around keyboard content guy who deserves more hyphens.