A Better Beginner’s Guide to Force Curves

A little over four years ago, I published an article titled ‘A Beginner’s Guide to Force Curves’ that served as some of the only introductory documentation out there teaching mechanical keyboard enthusiasts how to read and interpret force curves. While that article has done well in educating a good number of readers over the past few years, I have to admit that it has grown a bit outdated. As well, nobody else has stepped up to write any more introductory guides in that span of time, either. Rather than growing outdated due to the baseline information contained within aging out or fundamentally changing, this original beginner’s guide has become outdated because of just how much information I’ve gathered on force curves both explicitly and implicitly in the last four years. The largest single contributor to that bank of knowledge I’ve developed came in the form of a professional, lab grade force curve machine that was gifted to me by Drop and has since allowed me to crank out over 1,500 different force curves – a number which is nearly quintuple the amount that were available when the last guide was written. Fortunately, rather than calling my original guide to force curves “The” Beginner’s Guide to Force Curves my choice in referring to it simply as “A” guide will still mean that its relevant moving forward in time. However, I think it’s about due time that I make a newer, more updated, and more thorough guide too force curves. Perhaps a ‘Better’ Beginner’s Guide to Force Curves, just to stop me from screwing myself in the event of a third update to this in the future.

Before getting into this article, and a much more thorough and comprehensive coverage of all things related to and dealing with switch force curves, I would be wrong in not pointing to some of the documentation that is foundational to all of this. As I discussed all those years ago in the first beginner’s guide, part of what spurred on both my deep interest in switches as well as their force curves specifically was that of the work of HaaTa. HaaTa, for the few of you who aren’t aware of him, is one of the most well known members of the keyboard community who has gotten himself deeply involved in everything from opening Input Club and Kono Store, to amassing a collection of over 500 different keyboards, and even down to the lowly realm of measuring switches with a homemade force curve machine. To try and summarize his full list of accomplishments within the hobby and stories about all of those antics into any short number of sentences, let alone paragraphs, would be virtually impossible and so we’ll just stick to his work on force curves as that is the most relevant to the topic of conversation right now. Before such a thing was even remotely common in the hobby outside of a rare few eastern enthusiasts and actual switch manufacturers, HaaTa identified the value of force curves as tools for objectively discussing switches and first wrote about them in his article titled ‘The Problem with Mechanical Switch Reviews’. Unlike more modern content creators who are heavy on opinions and light on action, HaaTa didn’t just spend that article railing about the lack of use of force curves by the masses - he went out and managed to build his own force curve machine from semi-scrapped parts and began the very first community-led repository of switch force curves. He was then kind enough to further expand on that in his guide on ‘How to Read a Force Curve’. Reading these articles many, many years ago is what initially struck an interest in me one day collecting force curves of my own, so to not mention their influence on all of this work that I’ve completed here (as well as the fact that they’re actually just damn good reads) would feel incredibly wrong on my behalf. Go read these articles.

HaaTa’s ‘How To Read a Force Curve’

The Problem with Mechanical Switch Reviews

The ‘What’ and ‘Why’

If you’re here and reading this article now, there’s a good chance that you’ve probably come across a force curve before. It might have been a vaguely long time ago when looking to buy some switches on some random vendor’s storefront that you can’t quite recall now, or it could have been about thirty seconds before someone linked to you this article. Irrespective of how you ended up here, force curves are incredibly valuable charts and the data contained within them can provide insights into switches that simply can’t be captured well by dubious marketing tactics or just a list of random specifications about those switches. While force curves were still somewhat rare to see a handful of years ago, my recent push to collect as many of these as possible myself over the last couple of years has certainly helped push them a little bit more into relevancy. Alongside my push, though, there have also been increasing numbers of manufacturers and vendors who are starting to provide these on their switch sales pages too, so it’s probably in your best interest to actually know what they are and how they work. Force curves, as simply as I can put it, are graphs which show how heavy a switch feels underneath your fingertip at any given point where you could depress the stem to. While that alone is likely enough to get you a rough idea of what is going on here, that one sentence summary does not capture all of the nuance, technical depth, and insights about switches that can be squeezed out of these graphs if you know what you’re looking for. Before we just dive right into reading these graphs, though, it will help you get more into the headspace of force curves by understanding the physics behind them and the technology that is used to generate these graphs.

The How

Switching gears away from force curves for a minute, let’s move to mechanical keyboard switches since that is what we are trying to measure with force curves. At their most fundamental level, keyboard switches can be thought of as miniature machines which act to do one single thing – compress the spring inside of them. As you push the stem down, it compresses the simple, helical spring inside of it until it reaches some point at which it can’t be compressed anymore. Pulling your finger away, the stem begins to rise in the housing as the spring expands, slowly pushing the stem back into its resting position just like how it was when you first went to press it. Luckily for us, fairly elementary level physics has a pretty good understanding of how to map out this process and assign actual numbers to it. The action of depressing and releasing force on a spring can be described for simple spring models using the equation as outlined in Hooke’s Law.

Figure 1: Hooke's Law formula for simple helical springs.

Hooke’s Law, as you can see above, is a rather simply formula that relates the force that is being applied to a spring, ‘F’, with the amount of distance that the spring depresses, ‘x’. Between ‘F’ and ‘x’, you see that there is a proportionality constant that scales this relationship, ‘k’. This ‘k’ value is uninterestingly referred to as the “spring constant” and has a value that is both unique to each and every spring, and is based upon all of their features such as their materials, size, number of ‘threads per inch’, etc. No two springs can be assumed to have identical spring constants and these constants can only ever really be determined empirically at our level of understanding. If we took this equation and decided to plot the relationship between the force on the spring and the spring’s displacement, it would result in a straight line that has a slope of ‘k’. This is what is known as a Force vs. Displacement diagram. Knowing that force curves were rather simplistically described above as just being graphs of how heavy a switch feels at various different distances of it being pressed on, you probably have already put together that Force Curves are just fancifully named Force vs. Displacement diagrams made specifically for keyboard switches. This, by extension, means that whatever machines are being used to collect and produce force curves are largely just “Hooke’s Law readers”, right? While a bit overly simplistic, that’s not the most incorrect of thought processes about such. These force curve machines look a little something like this:

Figure 2: My own Imada FSA-MSL-0.4 force gauge and testing stand.

The photo above is the exact Imada FSA-MSL-0.4 force curve machine that I use to collect all of my force curves and it is comprised of two distinct parts – a force gauge sensor and an articulable moving slide that can be used to jog this sensor up and down. The actual force gauge, itself, is the large grey rectangular part with the buttons, and the actual sensor is connected to the little silver nub that is protruding out of the underside of the gauge. This entire device is securely attached to the stand with a slider that can be moved up and down with the fine tune silver adjustment knob on the right-hand side of the machine. In order to collect a force curve, I place a switch on the base of the machine with its stem located just below the little silver sensor nub, and then use this adjustment knob to push the gauge into the stem. After one full cycle of pressing the stem all the way into the bottom of the switch housing and releasing it to return back to rest, the machine automatically spits out the data needed to generate a force curve. The reason that this machine looks as fancy as it does, and the reason why it costs a whole hell of a lot of money, is because it some pretty high grade measuring equipment on it – so much so that it allows me to measure with a resolution of 0.1 gf and 0.001 mm of travel distance. (Don’t worry too much about those units, we’ll discuss those a bit further down.) However, do not think that this means that all force curve machines necessarily need to be this expensive or high tech in order to do their job. While homemade machines do suffer a small bit in terms of their accuracy and consistency as a nature of their construction, you absolutely can build your own force curve machines and there have been a few people (like HaaTa) who have managed to do so. Even more excitingly, I am aware of at least one company right now that is working on trying to design a force curve machine that would be more easily able to be mass produced for the community at large. Whether you choose to seek out a super expensive, lab grade device or build one your own, the most critical design aspect is that there has to be a tight relationship between the force readouts and displacement readouts. Without this close relationship, you simply can’t generate active force curves.

Figure 3: An example of a homemade prototype force curve machine. (Photo from Pylon on Geekhack)

Before wrapping up this section and moving into the actual reading of force curves part of this guide, I don’t want to just leave us thinking that keyboard switches are just a bunch of simple spring compressing machines. Switches are actually a tiny bit more complicated than that. In the vast majority of MX-style keyboards switches that have been made throughout time (e.g. not Hall Effect or Optical style switches), there are other components known as metal contact leaves that interface with the stems of the switches and are critical to producing keystrokes. More complexly, switch stems move up and down via springs in order to somewhat laterally press on and bend the larger of the two leaves in a switch to force it to either make or break contact with the smaller leaf to register or stop registering keystrokes. Since stems interact with and touch leaves in addition to springs, these leaves also have an impact on how a switch feels. Consider the somewhat lateral (and somewhat not) forces that the leaves of a switch exert on a stem via the free body diagram I mocked up below from my original guide on this subject:

Figure 4: Force vector diagrams showing the additional forces that leaves apply to the stem of a switch at various points throughout the downstroke.

As you can see from the diagram above, depending on where the stem is pressed into in a switch, the force that the leaf is exerting on the stem can be quite different. In a resting position like the image on the left, the majority of the force from the leaf is perpendicular to that of the direction of the force of the spring, which is represented by the vertical orange line. As the stem is pressed inwards though, the right most diagram shows you that the force becomes much more vertical and begins to have a greater component that is working in the direction or against the direction of the force from the spring. This fluctuation in force from the interface between the stems and the leaves of a switch will ultimately take our force curves from looking just like a simple like with a Hooke’s Law-style relation to curves that have a more nuanced and non-linear look. Now that those expectations are a little bit more tempered, let’s get into how to interpret and read force curves for the different types of switches that exist out there. We’ll get started with the simplest of switches in linears in order to get us all on the same page.

Reading Linear Force Curves

Figure 5: A standard force curve diagram for a Cherry MX2A RGB Black linear switch.

Behold! At the start of this section is a force curve of a Cherry MX2A RGB Black linear switch that I collected myself and will be referencing for a good majority of the rest of this section. While force curves found from sources other than me on the internet will vary somewhat in how they choose to display the data and construct their graphs, all of them will largely look and feel quite similar to this one. However, since I have quite the lengthy repository that I am pulling from in order to make this article, I will be pointing out both some of the general features that you need to be aware of when it comes to force curves as well as some of my own personal style choices that I think are helpful for reading these graphs. The first things that you should note on this graph are the units for each axis. The Y-Axis is labeled as ‘Force’ and carries units of ‘gf’, which is short for gram-force. Gram-force can be thought of as effectively equivalent to 1 gram of weight for all intents and purposes here as strictly speaking 1 gram force unit is equivalent to the weight of one gram of mass being acted on by Earth’s gravity. To the best of my knowledge, no switch force curves have yet been collected off planet, so it’s probably safe to assume this is true for all force curves which use units of gf. On some other force curves, you will occasionally see this force listed in ‘cN’ or ‘centinewtons’, instead. Since the conversion from gf to cN is 1 gf per 0.981 cN, you can more or less assume these to be equivalent for quick interpretation purposes. The X-Axis, labeled ‘Displacement’, has units of ‘mm’ or millimeters as the conventional design of MX style switches grants a total of roughly 4.00 mm of stem travel. While some switches will pull up much shorter than this, very few go significantly beyond this distance and thus it’s rare to see force curves for MX-style switches with X-Axes beyond 5.00 mm at their extreme.

Looking to the actual plot itself, you’ll note that instead of just one singular curve there are actually two differently colored lines on the force curve plot – a black one for the switch’s ‘downstroke’ and a gray one for its ‘upstroke’. These two lines are separated using colors here as they represent two distinct regimes of action for the Cherry MX2A RGB Black switches. The downstroke is the action of pressing down on the switch, causing the stem to move inwards from its resting position at 0.00 mm until it is depressed roughly 4.00 mm of displacement. (Visually, this black curve is read starting at the left-hand side and then moving towards the right.) The upstroke, on the other hand, is the action of removing force from the switch that has been pressed in all the way to 4.00 mm, and allowing the stem to slowly return upward to its resting position at 0.00 mm of displacement. (Visually, this gray curve is read starting at the right-hand side and then moving towards the left.) Aside from being separated due to being fundamentally different regions from one another when operating a keyboard switch, I’ve chosen to separate these curves as often times the downstroke portion (black curve) is the only thing that is actually felt by people using keyboard switches. Most often, people type not by slowly releasing their fingers off of a switch that they’ve pressed all the way in, but rather by fully disengaging from the keys in order to let them rise back to their resting place prior to pressing them again. As a result, most people are often disengaged from their switches while the gray upstroke portion of the force curve is actually occurring. Do note that sometimes the upstroke and downstroke curves for a force curve diagram are neither color corded nor labeled on force curves, and especially so for those made by manufacturers. In instances where this is not the case, always remember that the downstroke will be physically above that of the upstroke bottom line. This is (almost) always true for switches as they wouldn’t work otherwise!

Figure 6: Force curve diagram for a Cherry MX2A RGB Black switch with the progression of downstroke and upstroke curves labeled.

*The parenthetical ‘almost’ at the end of the last paragraph as there are the occasional times where you may encounter a ‘butterfly style’ force curve graph. All things you’ll learn about reading force curves in this article apply here for these special types of plots still, though these plots just mirror the upstroke over the vertical axis to allow for less cluttered comparisons of upstrokes and downstrokes of multiple switches. The butterfly style force curve for the Cherry MX2A RGB Black switch can be seen below:

Figure 7: A butterfly style force curve diagram for a Cherry MX2A RGB Black linear switch.

You’ve probably already noticed that there’s three distinctly separate ‘regions’ on the force curves for both the downstrokes and upstrokes instead of just a single, straight line as I pointed out would occur in the more physics-heavy section above. These regions are those of the vertical upright at the left-hand side of the graph, the vertical upright at the right-hand side of the graph, and the roughly flat portion in the middle. Each of these regions have different names that they’re referred to when discussing force curves. The first vertical region between 0.00 and 0.10 mm of displacement on the graph is that of the “start” of the switch. While this is almost instantaneous both in the Cherry MX2A RGB Black switch force curve here, as well as in the force curves of a good number of other switches, this region is important as it signifies the weight that is required to get the switch actually moving throughout its progression. Here on this plot, that starting weight for the Cherry MX2A RGB Black switches is somewhere around 44.0 gf. The long and flat-ish zone that comes after this is what will simply be referred to here as the “stroke”. Often times this region is the only part that is being talked about when discussing switch force curves, so this often carries a lot of contextually relevant names such as the ‘linear region’, ‘the tactile bump’ for tactile switches, or really just anything that isn’t the names of the start or this third and final section. Finally following this “stroke” region is that of the “bottom out region”, where a stem is firmly in contact with the bottom housing of the switch and can’t be depressed any further. Since there is nowhere else for the stem to be pushed after it makes contact with the bottom housing, it causes the force read by the force curve machines to skyrocket, and often times in a nearly vertical fashion.

Figure 8: Force curve diagram for a Cherry MX2A RGB Black switch with the 'start', 'stroke', and 'bottom out' regions highlighted and labeled.

Some of the more astute readers out there will have already likely found it a bit odd that the stroke region for the upstroke and downstroke curves of the Cherry MX2A RGB Black switch don’t quite look the same in the force curves above. This is not a feature that is unique to the Cherry MX2A RGB Black switches – it is actually present in almost all traditional MX-style switches. (In fact, this is explicitly why I drew the free body diagrams for the leaves of the switch above in Figure 4.) As you can now see manifested in the actual force curve readout for a switch, the angle of the leaves in the switch do push on the stems with different amounts of force depending on how far the stem is into the downstroke. The point at where the upstroke and downstroke force curves come together, around 2.50 mm in the force curve for the Cherry MX2A RGB Blacks, is the point at which the leaves entirely disengage with the stem and the stem is sitting below the point of contact with the leaves. During the upstroke of the switch, it is actually the stem re-engaging with the leaf that is applying an ever so slight upwards force on it that causes the perceived drop in force from 2.50 mm to 0.00 mm. On the contrary, the downstroke is heavier from 0.00 mm to 2.50 mm as it is attempting to push past the upward force of the leaves during this part of the stroke. The magnitude of this separation is somewhat different from switch to switch, though it is something that is present in all types of my traditional, MX-style keyboard switches which contain conduction leaves. As you might be able to imagine, since optical or Hall Effect style switches don’t contain leaves or any mechanisms which directly interact with the stems other than the springs in most instances, the force curves for these switches simply won’t have this separation between upstroke and downstroke curves through the stroke region.

Figure 9: A force curve diagram for the Hall Effect style Gateron Dual-Rail Magnetic Orange linear switch. Note the lack of separation between upstroke and downstroke curves.

Jumping around a slight bit, I want to take us back to the bottom out region of the force curve for the Cherry MX2A RGB Black switches that we discussed above as there actually are some differences in this region between different types of switches. While these differences aren’t related to if a switch is linear, tactile, or clicky, there are sometimes differences in this region as well as the transition between the stroke and bottom out regions that can occur if the switch is a “silent” switch. Rather than just having bottom outs that occur through plastic on plastic contact, traditional silent switches will have rubber or silicone dampening pads embedded in the stems that act to give a soft, squishy feeling to the bottom out when the stem is pressed in all the way. Since the normal transition from stroke to bottom out occurs from a hard, plastic-on-plastic collision, it is often steep, sudden, and very sharp in its transition. However, when silent switches employ these soft dampening pads that slowly compress into the bottom out of a switch, they will often have a more curved, arching transition from the stroke to the bottom out region. While this is super obvious in the force curve for the Outemu Silent Peach V3 switches below in Figure 10, this is not always nearly as obvious in silent switches as it depends on how firm or soft their dampening pads are, assuming they use that silencing mechanism at all.

Figure 10: A force curve diagram for the Outemu Silent Peach V3 silent linear switch. Note the more curved transition from stroke to bottom out regions.

Amidst all of the new ideas that I’ve now shoved into your head about force curves, and especially linear ones, I do want to plant the seed for now that there is actually more complex, nuanced interpretations to be gathered by looking deeper into these curves. And this is especially true even for pretty mundane force curves like the linear ones above. As part of a large and still ongoing amount of work I did for my article titled ‘On Differences In Linear Switches’, I was able to quantify differences between linear switches based on two different features that can be extracted from their force curves. If you’ve seen any of my switch reviews of linear switches prior to this article, you’ll have likely already encountered this data at the bottom of the performance block of the review in the section titled ‘Linearity’. If you haven’t read those reviews before, though, consider reading that article on differences between linear switches after finishing up this one. Briefly, though, the two features I use to quantitatively divide linear switches is that of their “linearity” and their “slope”. Linearity, as the name implies, is a quantification of how straight the stroke region is of a linear downstroke, and can help differentiate switches based on which ones are the most consistent in their force progression throughout their downstroke. The other quantity, slope, is a measurement of how much force is gained per unit of displacement throughout the downstroke of the linear switch. While it’s somewhat true that most linear switches do increase in force linearly throughout their stroke regions of their force curves, not all of them do it at the same rate; Some hardly change force at all over their downstrokes while some take off like absolute rocket ships. In the event you don’t believe me that linear switches can vary that much between one another, consider the following comparisons of downstroke stroke regions between various linears that I compiled for that short article. (And seriously go read that article if the graphs below pique your interest in the slightest!)

Figure 11: Comparison of slopes of the linear region for three different switches with equations for line of best fit included. Note that the highlighted values correspond to the 'Slope' discussed above.

Figure 12: Comparison of flatness of the linear region for three different switches with equations for line of best fit included. Note that the highlighted values correspond to the ‘Linearity’ discussed above.

Reading Tactile Force Curves

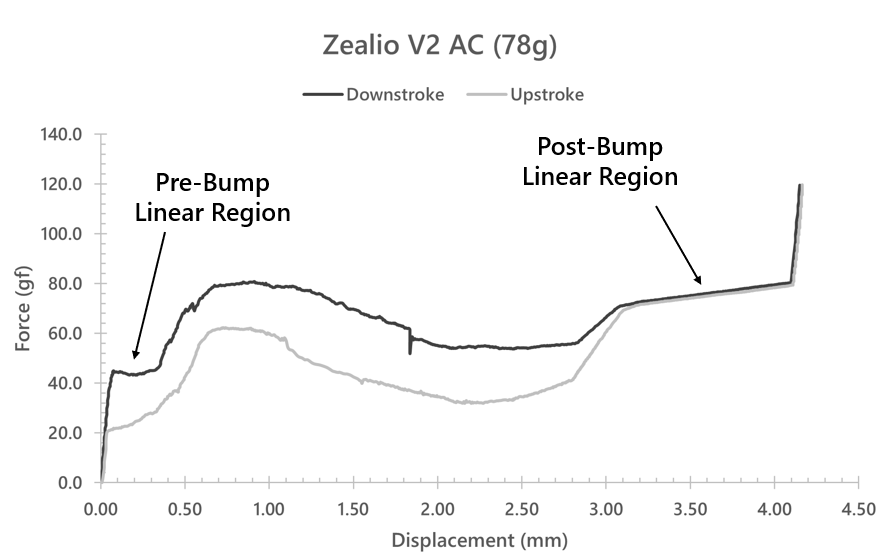

Figure 13: A standard force curve diagram for a 78 gram Zealio V2 tactile switch.

When it comes to looking at and analyzing force curves for tactile switches, you’ll find that almost all of the features discussed in the previous section on interpreting linear force curves also apply here as well. In fact, the linear force curve section was as long as it was because it covered a lot more of the fundamental aspect of discussing force curves rather than just focusing on “boring” old linear switches. With no sarcasm implied at all, this section is where the real fun with looking at force curves begins. Rather than having a flat stroke region, you can pretty clearly see that the Zealio V2 switches in the force curve above have a large wave that rises up and then drops off in force as you progress through the downstroke of it. Unsurprisingly, this wave in the downstroke of these switches is actually the numerical, force vs. displacement representation of the physical tactile bump of the heaviest Zealio V2 switches. However, it should probably be stressed rather early on in this section that what actually is the tactile bump in a force curve graph and what people are colloquially referring to when they are discussing tactile bumps is rarely the same thing. See, while the entire wave – both peak and valley – is what is known as the tactile bump in this force curve above, people often are only referencing the peak of that curve as that is all that they can really feel in normal operating conditions. Tactile bumps take relatively so much force to overcome that peak in force (sometimes known as the ‘peak force’) that people will often rocket past the valley portion of the curve and land straight into the linear post-bump region, represented here from 3.00 mm to 4.20 mm.

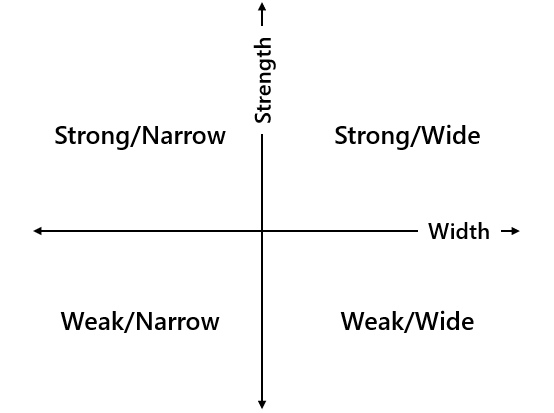

Figure 14: Force curve diagram for a 78 gram Zealio V2 switch with formal and colloquial references for “tactile bump” labeled.

Much like with linear switches, not all tactile switches are made equally either. As a result of this, there’s quite a bit of good discussion that can be had about all of the different shapes that these tactile bumps take on in force curves. While I wish that there was a hard and fast, quantifiable way that we could differentiate between tactile bumps similar to what I’ve pieced together for linear switches, there just simply isn’t such convention yet. (That isn’t for a lack of trying on my part, either. It is incredibly hard to quantify things as such and do it in a way that it’s actually useful to talk about and share.) Despite the lack of objective terms that can be used to describe tactiles, there are decent comparisons that can be drawn between them in terms of two concepts that can also be plotted on qualitative axes – ‘Strength’ and ‘Width’. ‘Strength’ is the qualitative term that I use to effectively refer to how much force it takes for someone to overcome the peak of the tactile bump relative to that of the linear regions around it. For example, while someone might assume that all tactile switches that have a peak force around 100 gf are rather ‘strong’, that tactile bump is going to feel a lot stronger if the switch starts out at 10 gf than for one that starts out at 90 gf before it hits its bump. The other qualitative discussion term, ‘Width’, is used to refer to how wide the actual tactile bump appears on a force curve for the switch. Translated into how this feels in hand, this is attempting to describe the differences between tactile bumps that quickly and rapidly occur and feel like a sudden blip as compared to those that are long, drawn out, and feel as if they develop over the entire downstroke of the switch. Again, these terms are only subjective though and should not be taken as objective nor absolute in their framing. Their usefulness is in allowing us to not only loosely categorize tactile switches but to also have productive conversations comparing them. Categorizations of tactile switches and some examples of what force curves for these types of switches might look like is as follows:

Figure 15: The four qualitative quadrants of tactile switches.

Figure 16: A force curve of the Momoka Shark switches as an example of a Strong/Narrow type of tactile switch.

Figure 17: A force curve of the JWICK T1 switches as an example of a Strong/Wide type of tactile switch.

Figure 18: A force curve of the Cherry MX2A RGB Brown switches as an example of a Weak/Narrow type of tactile switch.

Figure 19: A force curve of the Gateron Root Beer Float switches as an example of a Weak/Wide type of tactile switch.

Tactile bump strength and width are not strictly speaking the only features which are worth noting when it comes to tactile switches. As you may have been able to see in some of the last four force curves above this paragraph, tactile bumps aren’t exactly located in the same spot in their downstrokes from switch to switch. Some switches have bumps that start right at the onset of the stroke, while others suddenly pop up in the middle of their stroke and then disappear shortly thereafter. This difference is something is usually discussed as the ‘location’ of the tactile bumps, with switches being binned loosely into one of three categories – ‘early’, ‘middle of stroke’, or ‘late’. For those switches that are not wide enough to take up their entire downstroke, and thus have tactile bump positions that can be described using these terms, there also is another pair of phrases which you’ll occasionally hear tossed around when people discuss switches – ‘pre-bump linear region’ and ‘post-bump linear region’. (In fact, I’ve already used one of these phrases above!) With the tactile bump not taking up the full width of the stroke, switches often have linear regions of their stroke leading into or following after the tactile bump of the switch wraps up. Looking back to the force curve for the Zealio V2 switch that we looked at leading into this section, you can see that it actually has both pre- and post-bump linear regions.

Figure 20: Force curve diagram for a 78g Zealio V2 switch with pre- and post-bump linear regions labeled.

Reading Clicky Force Curves

Do you know what’s even more cool about discussing and analyzing force curves for clicky switches than linear or tactile switch force curves? Almost all of the terminology and categorization terms you learned above in the past two sections also applies here as well… except for the fact that they just generally aren’t used all. While there’s nothing stopping people from discussing the force curves of clicky switches using terms that describe how wide or strong their click mechanisms are, most people who are looking into clicky switches care infinitely more about the sound of their switches than how they analytically measure up using math and science. Further compounding the issue of discussing force curves for clicky switches is that they are significantly more varied in terms of their constructions and the number of mechanisms that are employed within the MX-style footprint to produce a noise. Even discounting a large group of clickies with some of the more uniquely designed mechanisms from recent years – including switches like Zeal’s 3-in-1 Clickiez, Novelkeys’ Cream Clickie, and Gateron Melodics – this still holds true for just the two common click-producing mechanisms in click jackets and click bars. Generally speaking, though, despite the wide variety that these curves come in, force curves collected for click bars and those collected for click jackets tend to look more or less similar to those that share a mechanism. Force curves for clicky switches using click jackets tend to have pretty noticeably different upstrokes and downstrokes, with a significant degree of noise present in especially their upstroke portions. Force curves for clicky switches using click bars, however, tend to be a bit more symmetrical, have a large plateau region that rapidly drops off vertically at the click in their downstroke, and tend to be ‘stronger’ than click jacket ones. An example force curve for each style of mechanism can be found below.

Figure 21: A force curve of the Cherry MX Blue switches as an example of a click jacket mechanism clicky switch.

Figure 22: A force curve of the Kailh Box Navy switches as an example of a click bar mechanism clicky switch.

One of the things that is readily apparent in the force curves for any type of clicky switch, irrespective of its mechanism, is that there is usually much more noise in the upstroke and downstroke curves than in linears or tactiles. While this is perhaps not the most unexpected of features when you consider just how chaotic click jacket mechanisms are in terms of both sound and in-hand feel, this often leads people to believe that this noise is due to scratch or poor part tolerancing. Resultingly, they then begin to believe that any degree of noise in any force curves is telling of how scratchy or well put together these switches are. To put it bluntly, this is extremely incorrect. In order to prevent you from falling into that group of confused beginners, we’ll go ahead and discuss one of the most important things that should be included in any good guide on interpreting data – a discussion on what these charts can’t actually tell you.

Where Reading Between the Lines Fails

Since I started building my repository of force curves a couple of years ago, I’ve been lucky enough to witness a steady increase in discussion surrounding force curves and some genuinely great insights pulled from such. However, I’ve also been witness to an alarming amount of completely incorrect assumptions about what can actually be read from force curves that was seemingly pulled from thin air and with no actual basis in reality. Even though I could write an entire separate article fully laying out how each and every one of these claims, and quite a few others, are incorrect, the short list below encompasses a few of the more common misunderstandings about force curves. Now you have no excuses for accidentally repeating these things as true!

-’The noise in the force curves’ lines are due to scratch.’

The force by which scratch acts on the stem of a switch, and especially the component of that force that is actually working in the vertical direction in line with the major contributing force to the force curve in the spring, is absolutely negligible even for super high resolution force grade machines like mine. To actually feel enough force from scratch to substantially register on a force curve machine, you’d have to line the slider rails of a switch with literal sandpaper. The noise that is present in force curves is due to background fluctuations in the force that the sensor is feeling because of how sensitive it is. For example, my machine is so touchy that when I have it turned on and about three feet away from my keyboard on my desk, I can actually see the force jumping up and down by 0.2 to 0.4 gf just from the force of me typing on my keyboard. Super sensitive pieces of equipment like this one have a sensitivity that has to be accounted for, and the general noise you see in the force curves for most switches is simply an artifact of that degree of sensitivity. Lower grade machines won’t have as much noise as they’re not as sensitive to these tiny, incremental changes in force.

-’You can tell how well switches are lubed based on their force curves.’

In a similar vein of rationale as what was described above for not being able to reach scratch in force curves, you definitely can’t tell if a switch is lubed or rather how well it is lubed based on their force curves. Again, the vertical force applied from lube acting to reduce friction between a stem and a bottom housing is so negligible that you simply won’t ever be able to read that on a machine. The only way that you could convincingly tell if there was lube or not in a switch using a force curve machine would be to first egregiously overlube a switch to such a degree that you actually damage its ability to function prior to sticking it under the force curve sensor. I’m talking overlubing like filling a switch’s entire free space with Vaseline, not just going a little bit heavy handed with the Krytox.

-’The force curves for broken in switches will be noticeably different than their stock ones.’

This one is phrased as a definitive statement a bit maliciously on my part as it actually started in the form of a relatively realistic question from a Discord server user who definitely knows a good amount about force curves and how they work. While I immediately contended that there’s almost certainly not a significant enough change in the performance of switches over the process of them breaking in that it could actually affect their force curve readouts, I also didn’t just stop at that claim. Instead, for the dozens of reviews since this question arose, I have included force curves not only for the stock versions of the switches but also for those broken in to 17,000, 34,000, and 51,000 actuations as part of my break in testing. To summarize all of those results up for you, I have yet to see the force curves for these switches significantly nor consistently change as a result of the breaking in process that I’ve subjected them to.

The State of Force Curves Today

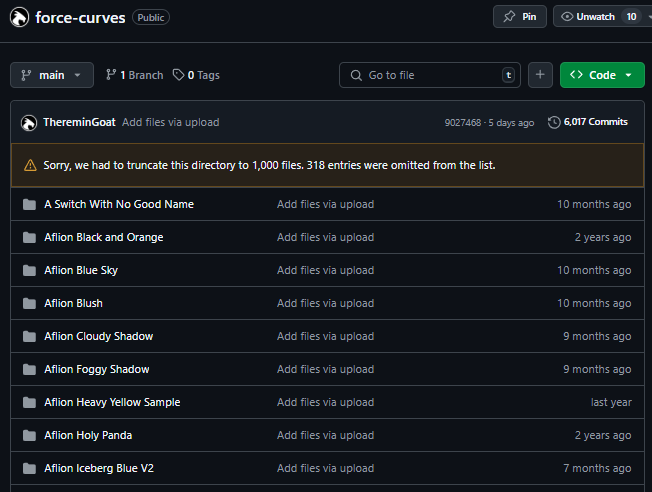

Without a doubt, the most significant change that has taken place in force curves since writing my original beginner’s guide about them has been my acquisition and subsequent abuse of a lab grade force curve machine. Gifted to me back in May of 2022 by the CEO of Drop with the explicit request that I use it to produce as many force curves as possible, I’ve largely been able to take on work that I could only describe as a far distant fantasy in my original guide. While I have yet to necessarily cover all of the bases and data-driven ideas that I had described all of those years ago, the amount of work that has been accomplished is pretty substantial in my opinion. As of the time of writing this guide, I’ve posted 1,538 different force curves for 1,327 different modern, MX-style mechanical keyboard switches on my Force Curve Repository hosted on GitHub. In addition to collecting, processing, and displaying all of this data, I’ve also started and continued the expansion of my ‘Linearity’ project, attempting to quantify differences between linear switches in terms of both their slope and linearity. As of the time of writing, this data processing has taken place for 672 of the 1,004 linear switch force curves I’ve collected. Furthermore I’ve also used all of this data to not only supplement my own reviews both in the direct descriptions of switches as well as comparisons between them, but also to help several different vendors display the performance of their switches and prototypes on their sales pages. For those of you who have never encountered my Force Curve Repository on GitHub before, it looks something like this:

Figure 23: Front facing view of the what my Github Force Curve Repository looks like.

As can be seen, each different switch gets its own file. Within each file there are a series of documents which serve each purpose:

< Switch Name > Raw Data CSV

- This file is the raw data as output from the “low resolution” setting on my force curve machine.

< Switch Name >_HighResolutionRaw

- This CSV file contains the raw data output from the “high resolution” setting on my force curve machine. While I don’t process this data, it is available for those who wish to use it.

< Switch Name > Data Construction XLSX

- This file contains all of the force curve charts that I’ve generated as well as any of the data processing that I did in order to construct those plots from the Raw Data CSV file.

< Switch Name > Linearity (If Linear)

- If a switch is linear, this is a separate XLSX sheet where I carried out the data processing in order to determine the switch’s linearity and slope.

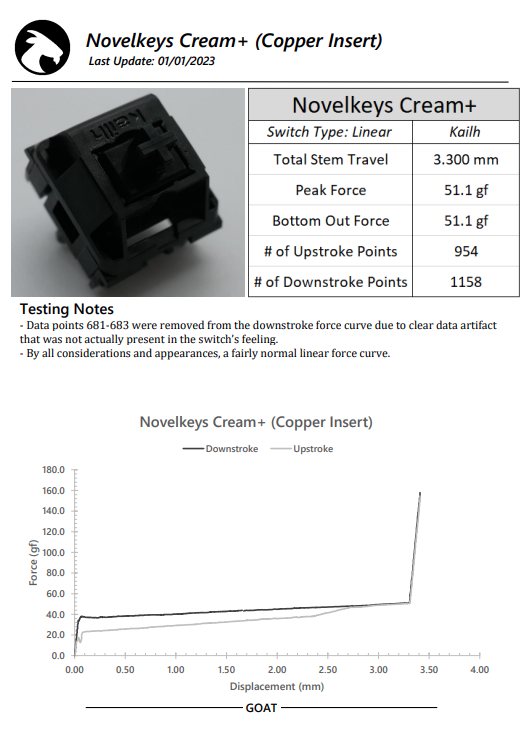

< Switch Name > PDF

- This file contains all of the force curves and summarizes information related to the collected force curves for a switch. There are multiple force curves present in each PDF including a traditional style one, a butterfly style one, and two separate graphs for just the downstroke and just the upstroke curves. All are presented in the exact same style as shared here. An example of what the first page of each PDF looks like can be seen below:

Figure 24: Example image of what the first page of every PDF looks like in my force curve repository.

Furthermore, underneath the ‘Archive’ tab of my website, there is a link to a Google Drive called the ‘Switch Measurement Sheet’ that contains several different switch measurement sheets within it despite what the name implies. In this folder are two separate composite Excel sheets – one that contains all of the information in the table in the example above for all switches I’ve collected force curves for before and one that contains a similar summary for the ‘Linearity’ project. I highly recommend referencing these composite sheets.

Despite making up the currently available majority of force curves for modern mechanical keyboard switches out there, my work does not exist in a vacuum nor am I the only person to have a repository of force curves available to the general public. As discussed at the top of this guide, HaaTa has his own repository that he has hosted on his plotly account and it contains approximately 290 different curves. Unlike mine, HaaTa’s has ventured into measuring some vintage switches such as Alps and some vintage Hall Effect switches. The other known repository is that of Pylon, the designer of the Boston keyboard and their very own force curve machine. With this machine, they’ve amassed around 200 force curves on their own Github, exploring some frankenswitch combinations a little more liberally than either HaaTa or I. While there are no more repositories of this sort of data that I am aware of, there have been some pushes by other third party members of the community to make data visualization tools powered by these different repositories. The single most robust one I’ve encountered to date is that of hearlden’s ‘SwitchesDB’. This website rather seamlessly allows you to side-by-side compare and overlay force curves from all three repositories, and it appears to be rather frequently updated to match my consistent upload schedule. As I’ve described several times over in various formats prior, I have no intent to create a visualization tool like such of my own as I am not and will never be literate enough in programming languages to make such a thing possible. I am perfectly glad to continue collecting data and supplementing those users who wish to make such tools, however. All of my data for my force curves has been and forever will be publicly available for this reason.

Final Conclusions

Here we are, once more, at the end of a beginner’s guide for force curves. Hopefully this one is, as the name implies, better than the last one. This is just about everything you need to know in order to have an above average idea of how force curves are collected and how to interpret them, and in this day and age that’s becoming increasingly important for switches. More vendors, more manufacturers, and hopefully someday soon more enthusiasts are posting increasing numbers of force curves to help supplement all of the other data, opinions, and marketing points out there for the seemingly endless number of switches. Knowing what you can and should extract from these curves will be invaluable as that number continues to grow. Obviously, another big part of learning about switches and drawing conclusions about them is rooted in experience from trying a wide range of switches in hand and that should not be replaced, even partially, by reading and interpreting force curves. At the end of the day, switches are meant to be used in keyboards and underneath fingers, and there’s plenty of ways switches end up in builds that feel nothing quite like what their force curves would suggest. Trust me, I’ve encountered this quite a few times when looking at force curves during my full length review preparations. Hopefully this guide will stand the test of time a little bit better than the last one did over that very long stretch of four years in time. Well, maybe not too hopefully – it might be a good sign that I have to rewrite this again at some point in the future after I’ve figured out how to quantify tactility in switches as well! Until then, though, enjoy looking at some force curves.

Sponsors/Affiliates

Mechbox UK

- A wonderful UK based operation which sells singles to switches that I’ve used above in my comparisons for collectors and the curious alike. Matt has gone out of his way to help me build out big parts of my collection, and buying something using this link supports him as well as my content!

KeebCats UK

- A switch peripheral company based out of the UK which sells everything switch adjacent you could ask for, they’ve been a huge help recently with my film and lube supply for personal builds, and they want to extend that help to you too. Use code ‘GOAT’ for 10% off your order when you check them out!

proto[Typist] Keyboards

- An all-things keyboard vendor based out of the UK, proto[Typist] is a regular stocker of everything from switches to the latest keyboard and keycap groupbuys. While I’ve bought things from the many times in the past, they also are a sponsor of my work and allow me to get some of the great switches I write about!

Divinikey

- Not only do they stock just about everything related to keyboards and switches, but they’re super friendly and ship out pretty quick too. Divinikey has been a huge help to me and my builds over the last year or two of doing reviews and they’ll definitely hook you up. Use code ‘GOAT’ for 5% off your order when you check them out!

ZealPC

- Do they really need any introduction? Zeal and crew kicked off the custom switch scene many years ago with their iconic Zealios switches and the story of switches today couldn’t be told without them. Use code ‘GOAT’ (or click the link above) for 5% off your order when you check them out!

MechMods UK

- A rising vendor based in the UK, Ryan and crew have been a pleasure to work with and have nearly everything you’d need to build your first or fourteenth keyboard. Go build your latest or greatest one right now with them by using code ‘GOAT’ at checkout for a 5% discount!

Dangkeebs

- A longtime supporter of the website and the collection, Dangkeebs has quite possibly the widest variety of switches of any vendor out there. Not only is their switch selection large, but it rotates and is constantly adding new stuff too. You’re going to need 5% off your order with my affiliate to save off the cost of all those switches!

SwitchOddities

- The brainchild of one my most adventurous proxies, SwitchOddities is a place where you can try out all the fancy, strange, and eastern-exclusive switches that I flex on my maildays with. Follow my affiliate code and use code ‘GOAT’ at checkout to save 5% on some of the most interesting switches you’ll ever try!

Cannonkeys

- Does anybody not know of Cannonkeys at this point? One of the largest vendors in North America with keyboards, switches, keycaps, and literally everything you could ever want for a keyboard always in stock and with an incredibly dedicated and loving crew. Follow my affiliate link above in their name to support both them and I when you buy yourself some switches!

Kinetic Labs

- One of the most well-rounded keyboard vendors out there, Christian and crew have been supporters of all my switch and switch-adjacent needs for some years now. I’m honored to have them as an affiliate and think you should check them out using my affiliate link above to support both them and I when you check out their awesome products!

Keebhut

- Want to try out some switch brands that fly under most vendor’s radars? Keebhut is always seeking out that next latest and greatest and has been super helpful in hooking me up with new brands over the past year. They are all about sharing that love as well, and want to give you 5% off your next order with them when you use code ‘GOAT’ at checkout!

Kailh

- No, you’re not mistaken – this is actually that Kailh that manufactures switches. As one of the longest running manufacturers in the hobby, they have a massive variety of switches available over on their website at any point in time. I’m lucky to be affiliated with them now, and so consider using my affiliate link above when ordering some Kailh switches to support me!

Further Reading

HaaTa’s How to Read a Force Curve

The Problem with Mechanical Switch Reviews

HaaTa’s Plotly Force Curve Repository

Pylon’s Force Curve Repository

Herald’s Deskthority Announcement of SwitchesDB